Printed circuit boards are mainly used in products of information technology, communications, automobiles, semiconductors, consumer electronics, etc. Not only do permanent materials such as substrates, interlayer, outermost solder protection and soldered connection materials differ based on the requirements of different products, but the requirements of indirect materials used in the manufacturing process will also be different.

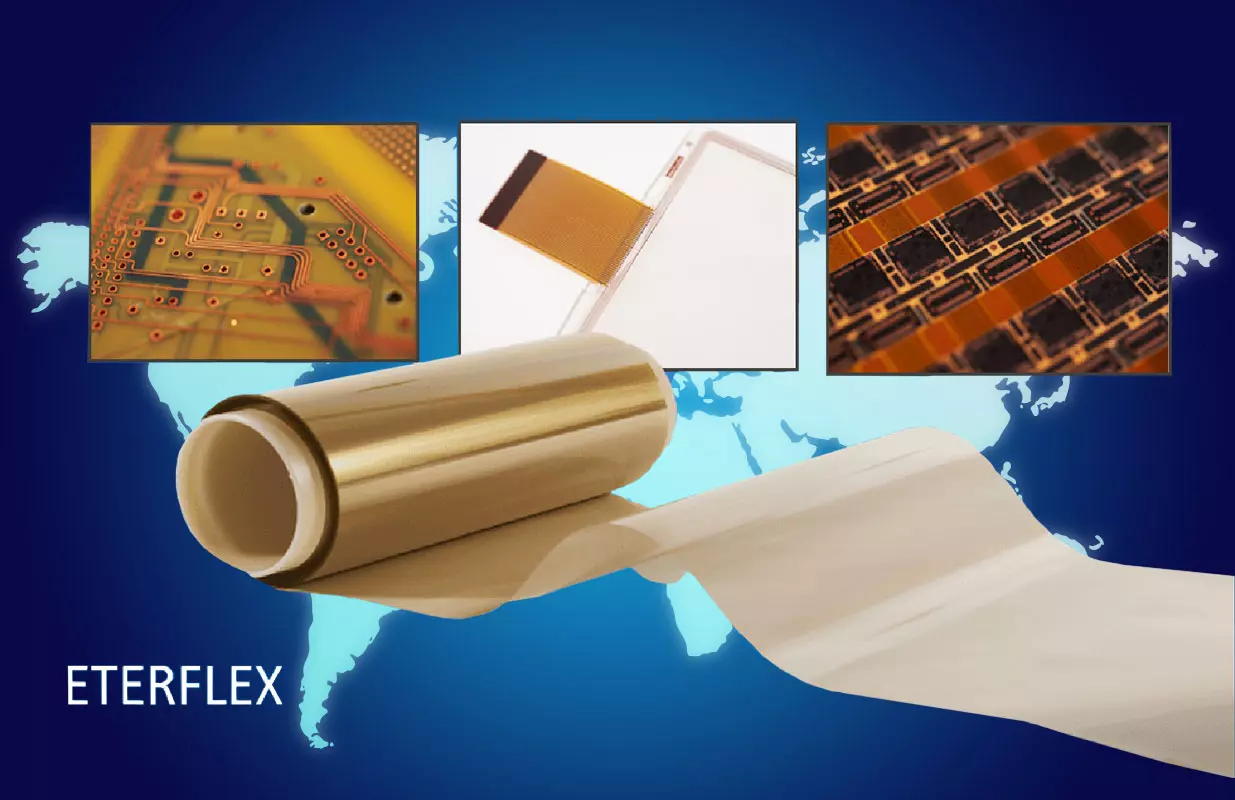

Based on the materials used, process technology and product applications, printed circuit boards can be mainly divided into different products such as Rigid PCB, Flexible PCB, Rigid-Flexible Composite PCB and IC boards. In recent years, because of the rapid development of intelligent products, the trend of various PCB products has accelerated toward compact sizes and high-density circuit layouts. The technical requirements for additional layers of fine lines, pore size and high alignment accuracy are also rising.

Our company's latest development, Dry Film Photosensitive Polyimide, like Liquid Photosensitive Polyimide, is mainly divided into two types, i.e., PAA Type (Pure Polyimide) and SPI Type (Low Post-Cure Temperature). The products can be designed, produced and developed according to the specific application and process requirements of the customers.