| Item Name |

Characteristics |

Applications |

Data Sheets |

| ETERCURE 6770T |

‧Easy dyeing

‧Good adhesion

‧Printable

‧Easy for laser engraving

‧Halogen-free products

‧RCA>50

|

UV VM topcoat (aluminum, tin, indium) |

|

| ETERCURE 6770T-2 |

‧Easy dyeing

‧Good adhesion

‧Hot stamping

|

UV VM topcoat (aluminum, tin, indium, chromium) |

|

| ETERCURE 6770T-1B |

‧Can add color concentrates

‧Good alkali resistance

‧RCA150

|

UV VM topcoat (aluminum, tin, indium) |

|

| ETERCURE 6770T- 5C |

‧Good leveling

‧Good heat resistance

‧RCA70-80 times

|

UV VM topcoat (aluminum, tin, indium) |

|

| ETERCURE 6760U-9D |

‧Good anti-sag

‧Good leveling

‧Halogen-free products

|

UV VM basecoat (ABS, PC/ABS, PC) |

|

| ETERCURE 6760U-6A |

‧Good anti-sag

‧Good leveling

‧High halogen products

|

UV VM basecoat (ABS, PC/ABS, PC) |

|

| ETERCURE 6760U |

‧General products

‧High halogen

|

UV VM basecoat (ABS, PC/ABS, PC) |

|

| ETERCURE 6769U-5 |

‧PP film needs flame treatment until 36dyne/cm |

UV VM basecoat (PP,PET) |

|

| ETERCURE 6760U-10D |

‧Good leveling

‧High halogen products

|

UV VM basecoat (ABS, PC/ABS, PC) |

|

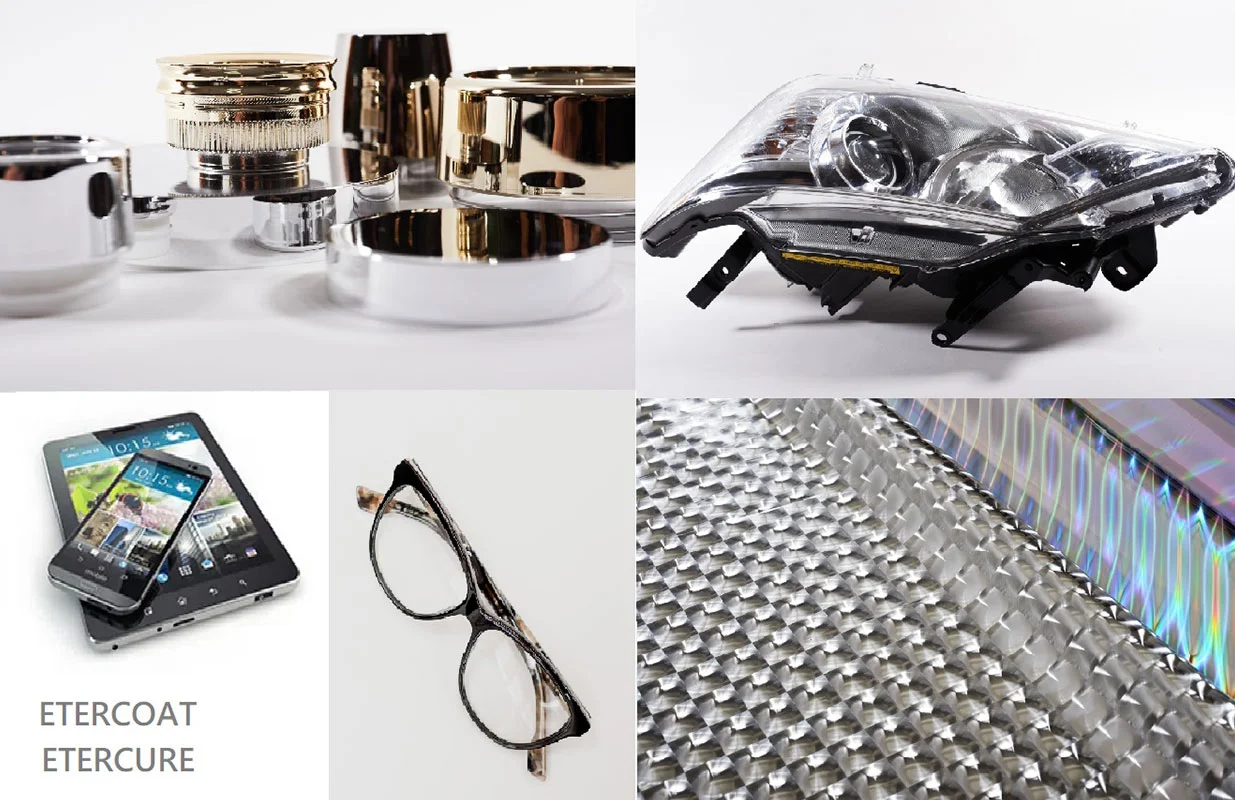

| ETERCURE 6737UA |

‧PC:110℃×3 hours

‧PPC:135℃×3 hours

‧ABS:80℃×3 hours

‧ABS:70℃×40 minutes

‧Heat-resistant ABS:85℃×3 hours

|

Automotive headlight thermosetting basecoat (PPC/PC/ABS) |

|

| ETERCURE 661 |

‧Fast curing

‧Low skin irritation

‧Better flexibility

|

Labels, coated paper, wrapping paper, magazines, book covers, greeting cards |

|

| ETERCURE 663 |

‧Fast curing

‧Low skin irritation

‧High hardness

|

Labels, coated paper, wrapping paper, magazines, book covers, greeting cards |

|

| ETERCURE 6673E |

‧Excellent resistance to fingernail scratching

‧Excellent defoaming

|

Packaging and general printing |

|

| ETERCURE 6682-100 |

‧Economical

‧High solid content products

‧Dilutable

|

Labels, coated paper, wrapping paper, magazines, book covers, greeting cards |

|

| ETERCURE 6671GNBS |

‧No slip agent added

‧Suitable for hot stamping

(100% non-wax products available)

|

Labels, coated paper, magazines, wrapping paper |

|

| ETERCURE 661-15 |

‧Fast curing

‧Low skin irritation

‧Better flexibility

|

Labels, coated paper, wrapping paper, magazines, book covers, greeting cards |

|

| ETERCURE 6682-85 |

‧Economical |

Labels, coated paper, wrapping paper, magazines, book covers, greeting cards |

|

| ETERCURE 663-9 |

‧Highest viscosity

‧Suitable for lithographic printing

|

Labels, coated paper, wrapping paper, magazines, book covers, greeting cards |

|

| ETERCURE 6673D |

‧Excellent resistance to fingernail scratching

‧Better defoaming

|

Packaging and general printing |

|

| ETERCURE 661-13 |

‧Fast curing

‧Low skin irritation

‧Better flexibility

|

Labels, coated paper, wrapping paper, magazines, book covers, greeting cards |

|

| ETERCURE 6835-2A |

‧Good protection foraluminum, silver and silicon reflective layers

‧Not easy to produce bubbles during disc bonding

|

DVD/DVD-Rdisc glue (pre-recorded/recordable) |

|

| ETERCURE 6803-9A |

‧Low viscosity

‧Good light and yellowing resistance

‧Good adhesion strength

‧Good protection for aluminum and silver reflective layers

|

DVD/DVD-Rdisc glue (pre-recorded/recordable) |

|

| ETERCURE 6804 |

‧Low viscosity

‧Good adhesion strength

‧Good protection for aluminum and silver reflective layers

|

DVD/DVD-Rdisc glue (pre-recorded/recordable) |

|

| ETERCURE 6803-24 |

‧Low viscosity

‧Fast curing

‧Good protection for aluminum and silver reflective layers

|

DVD/DVD-Rdisc glue (pre-recorded/recordable) |

|

| ETERCURE 6803-7 |

‧Good light and yellowing resistance

‧Good protection for aluminum and silver reflective layers

|

DVD/DVD-Rdisc glue (pre-recorded/recordable) |

|

| ETERCURE 6808 |

‧Fast curing

‧Good protection for silver reflective layers

|

DVD/DVD-Rdisc glue (recordable) |

|

| ETERCURE 6803-8 |

‧Low viscosity

‧Good protection for gold, silver, silicon and aluminum reflective layers

|

DVD/DVD-Rdisc glue (pre-recorded/recordable) |

|

| ETERCURE 6803-5 |

‧Fast curing, suitable for flashing type UV lamp

‧Good protection for aluminum and silver reflective layers

|

DVD/DVD-Rdisc glue (pre-recorded/recordable) |

|

| ETERCURE 6803-2 |

‧Small shrinkage

‧Good protection for silver reflective layers

|

DVD/DVD-Rdisc glue (recordable) |

|

| ETERCURE 6905-9D |

‧Fast curing

‧Good protection for aluminum and silver reflective layers

|

CD/CD-R-Rdisc glue (pre-recorded/recordable) |

|

| ETERCOAT 708-2 SERIES |

‧Good transparency

‧Bright colors

|

Middle coat and topcoat of aluminum coating layers in cosmetics and mobile phones |

|

| ETERCOAT 708-3 SERIES |

‧Good transparency

‧Bright colors

‧Good miscibility

‧Halogen-free

|

Middle coat and topcoat ofaluminum coating layers in 3C electronic products such as mobile phones |

|

| ETERCOAT 708-4 SERIES |

‧Good transparency

‧Good miscibility

‧Bright colors

‧Halogen-free

|

Middle coat and topcoat of aluminum coating layers in cosmetics and mobile phones |

|

| ETERCOAT 708-5 SERIES |

‧Good transparency

‧Bright colors

|

Middle coat and topcoat of aluminum coating layers in cosmetics |

|

| ETERCOAT 1870-1 |

‧Good adhesion to PET and PVC, used as a primer to help bonding the ink layers

‧High temperature curing, short curing time, easy to operate for the printing industry

|

Film treatment agent(PET, PVC) |

|

| ETERCOAT 1870-2 |

‧Good adhesion to PET and PVC, used as a primer to help bonding the ink layers

‧High temperature curing, short curing time,recoatable for ink, better adhesion, easy subsequent printing

|

Film treatment agent(PET, PVC) |

|

| ETERCURE 6765-4 |

‧Excellent scratch and stain resistance

‧Low rainbow grain in coated surface view

|

Optical protective film HC |

|

| ETERCURE 5537-671 |

‧Excellent scratch and solvent resistance

‧Small shrinkage

‧Good coated surface view, few defects

|

Optical protective film HC |

|

| ETERCURE 6765-25 |

‧UV adhesive for transferring patternsof nickel plate onto PET film

‧Aluminum-platable

‧Suitable for glue pouring or spreading machines

‧Good de-filming

|

UV transfer adhesive(platable) |

|

| ETERCURE 80542 |

‧General refractive index

‧Excellent handling characteristics

|

BEF front coating |

|

| ETERCURE 80480 |

‧Excellent anti-scratch hardness and anti-static properties (1011-12) |

BEF back coating |

|

| ETERCURE 6767-70H |

‧Excellent scratch and solvent resistance

‧Suitable for thin coatings after dilution

|

Insulation filmHC |

|

| ETERCURE 6767-70G |

‧Excellent scratch and solvent resistance

‧Good adhesion to dyed PET film

‧Suitable for thin coatings

|

Insulation filmHC |

|

| ETERCURE HC-102 |

‧Hot baking |

PC HC |

|